In the industrial sector, especially in environments where explosive gases, vapors, or dust are present, the selection of appropriate position sensors is crucial for ensuring safety and operational efficiency. As a supplier of explosion - proof and intrinsically safe equipment, I often encounter customers who are confused about the differences between explosion - proof and intrinsically safe position sensors. In this blog, I will delve into these differences to help you make informed decisions when choosing the right sensors for your applications.

1. Basic Definitions

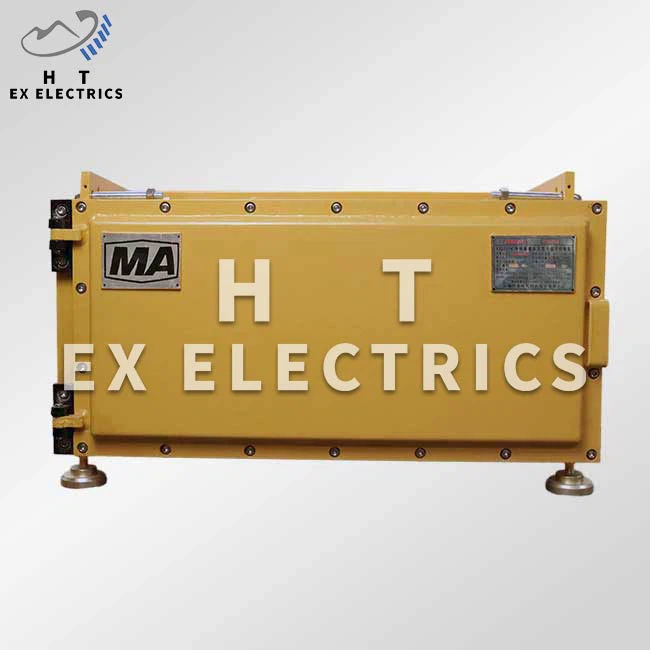

Explosion - proof Position Sensors

Explosion - proof position sensors are designed to contain an internal explosion within the sensor housing. They are built with robust enclosures that can withstand the pressure generated by an internal explosion without rupturing. This prevents the explosion from spreading to the surrounding explosive atmosphere. These sensors are typically made of strong materials such as cast iron or stainless steel, and the enclosures are designed with tight seals to prevent the passage of explosive gases or dust.

Intrinsically Safe Position Sensors

Intrinsically safe position sensors, on the other hand, are designed to limit the energy available in the electrical circuits to a level that is too low to ignite an explosive atmosphere. They achieve this by carefully controlling the electrical parameters such as voltage, current, and power. These sensors are often used in areas where the risk of explosion is high, and any spark or high - energy source could potentially trigger an explosion. You can learn more about Intrinsically Safe Explosion - proof System.

2. Design and Construction

Explosion - proof Sensors

The design of explosion - proof position sensors focuses on the mechanical strength of the enclosure. The enclosures are engineered to withstand high - pressure explosions that may occur inside. They have thick walls and are often designed with flame paths. Flame paths are narrow channels that allow the explosion pressure to be released in a controlled manner while preventing the passage of flames. These sensors also require proper installation and grounding to ensure their effectiveness.

Intrinsically Safe Sensors

Intrinsically safe sensors are designed with low - power components. They use special electrical circuits and components that are carefully selected to limit the energy. For example, they may use resistors to limit current, and capacitors to limit stored energy. The wiring of intrinsically safe sensors is also carefully designed to prevent any energy build - up that could lead to an explosion. You can find more information about Intrinsically Safe Explosion Proof.

3. Safety Mechanisms

Explosion - proof Sensors

The safety mechanism of explosion - proof sensors is based on containment. If an explosion occurs inside the sensor due to a fault or a short - circuit, the enclosure will prevent the explosion from reaching the outside environment. However, it is important to note that these sensors do not prevent the explosion from occurring; they only prevent its spread.

Intrinsically Safe Sensors

Intrinsically safe sensors prevent explosions from occurring in the first place. By limiting the energy in the electrical circuits, they ensure that there is not enough energy to ignite an explosive atmosphere. This is a more proactive approach to safety compared to explosion - proof sensors.

4. Installation and Maintenance

Explosion - proof Sensors

Installation of explosion - proof sensors requires strict adherence to safety regulations. The enclosures must be properly sealed, and the sensors must be installed in a way that allows for easy access for maintenance. Maintenance of these sensors often involves checking the integrity of the enclosure, the tightness of the seals, and the proper functioning of the internal components. Any damage to the enclosure can compromise the safety of the sensor.

Intrinsically Safe Sensors

Intrinsically safe sensors are generally easier to install and maintain. Since they do not rely on a strong enclosure for safety, the installation process is less complex. However, it is still important to ensure that the wiring and the electrical connections are properly made to maintain the intrinsic safety. Maintenance mainly involves checking the electrical parameters and the functionality of the low - power components.

5. Application Scenarios

Explosion - proof Sensors

Explosion - proof sensors are commonly used in areas where the risk of explosion is moderate, and where the presence of high - power equipment is necessary. For example, in oil refineries, they can be used in areas where large pumps or motors are located. These sensors can withstand the harsh industrial environment and the potential for internal explosions.

Intrinsically Safe Sensors

Intrinsically safe sensors are preferred in areas where the risk of explosion is very high, such as in chemical plants, mines, and grain silos. In these environments, even a small spark can cause a catastrophic explosion, so the use of sensors that prevent explosions from occurring is essential.

6. Cost Considerations

Explosion - proof Sensors

Explosion - proof sensors are generally more expensive than intrinsically safe sensors. This is due to the high - cost materials used in their construction, such as thick - walled enclosures and high - strength alloys. Additionally, the installation and maintenance costs of explosion - proof sensors are also relatively high.

Intrinsically Safe Sensors

Intrinsically safe sensors are often more cost - effective in the long run. Although the initial cost may be comparable to explosion - proof sensors in some cases, the lower installation and maintenance costs make them a more economical choice over time.

7. Certification and Standards

Explosion - proof Sensors

Explosion - proof sensors must comply with strict international and national standards. These standards define the requirements for the design, construction, and testing of explosion - proof equipment. For example, in Europe, the ATEX directive sets the standards for explosion - proof equipment, while in the United States, the National Electrical Code (NEC) provides guidelines.

Intrinsically Safe Sensors

Intrinsically safe sensors also need to meet specific standards. These standards focus on the electrical safety and the energy limitations of the sensors. Compliance with these standards is essential to ensure the safety and reliability of the sensors in explosive environments.

Conclusion

In summary, both explosion - proof and intrinsically safe position sensors play important roles in ensuring safety in explosive environments. Explosion - proof sensors are designed to contain internal explosions, while intrinsically safe sensors prevent explosions from occurring by limiting electrical energy. The choice between the two depends on various factors such as the level of explosion risk, the application scenario, installation and maintenance requirements, and cost considerations.

As a supplier of explosion - proof and intrinsically safe equipment, we are committed to providing high - quality sensors that meet the strictest safety standards. If you are in the process of selecting position sensors for your explosive environment, we encourage you to contact us for a detailed consultation. Our team of experts can help you determine the most suitable sensors for your specific needs and guide you through the procurement process.

References

- International Electrotechnical Commission (IEC) standards on explosion - proof and intrinsically safe equipment.

- ATEX directive for explosion - proof equipment in Europe.

- National Electrical Code (NEC) in the United States.